The Endeavor Health Skokie Hospital is a 450,000-square foot, 150-bed comprehensive hospital. This large-scale plant accommodates growth and addresses the need for equipment upgrades.

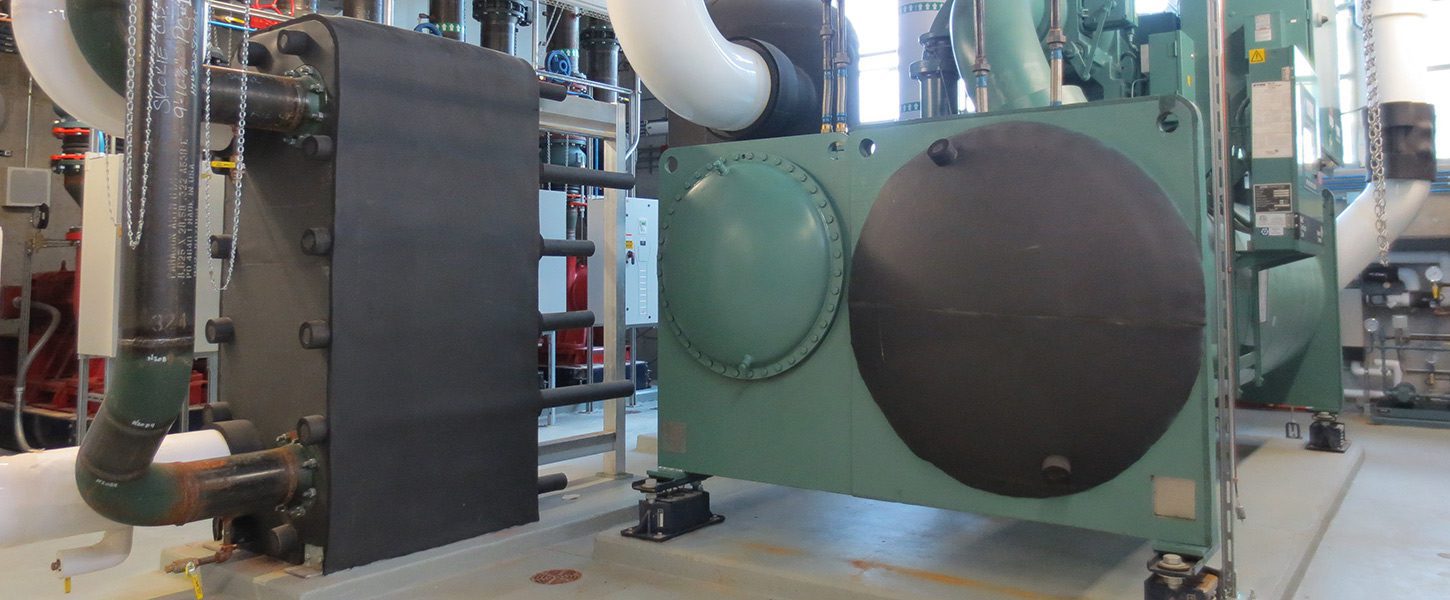

- The chiller plant consists of four 1000-ton centrifugal chillers with variable frequency drives (VFDs) and two two-cell cooling towers with VFDs and discharge sound attenuation.

- Chilled water distribution is via a variable-primary system with four 75-hp pumps. The condenser water system is variable flow with four 75-hp pumps.

- A hydronic economizer using a winterized cooling tower and plate-and-frame heat exchanger provides winter cooling for year-round loads.

- Four 1,700-MBH condensing water heaters with a 750-gallon storage tank provide domestic hot water. A new hospital domestic water service with 1,500-gpm triplex variable-speed pressure-boosting system was provided, as well as a new hospital fire protection service with a 100-hp fire pump.

- The new boiler plant includes four 400-hp medium-pressure steam boilers using natural gas with fuel oil back-up, with boiler oxygen trim, boiler blow-down heat recovery, and a boiler stack economizer.

- A reverse osmosis water system provides boiler make-up water and minimizes the use of boiler chemicals.

- The back-up power system comprises two 1,500-kW fuel oil emergency generators with super-critical-grade silencers, intake and exhaust acoustic louvers, and intake and exhaust silencers.

- A 20,000-gallon underground fuel oil storage tank, pumping system, and day tanks provide fuel oil to the generators and steam boilers.

- A computational fluid dynamics re-ingestion study was performed to determine proper stack height to avoid/minimize re-ingestion.

Exterior Hospital Photo: Jon Hillenbrand