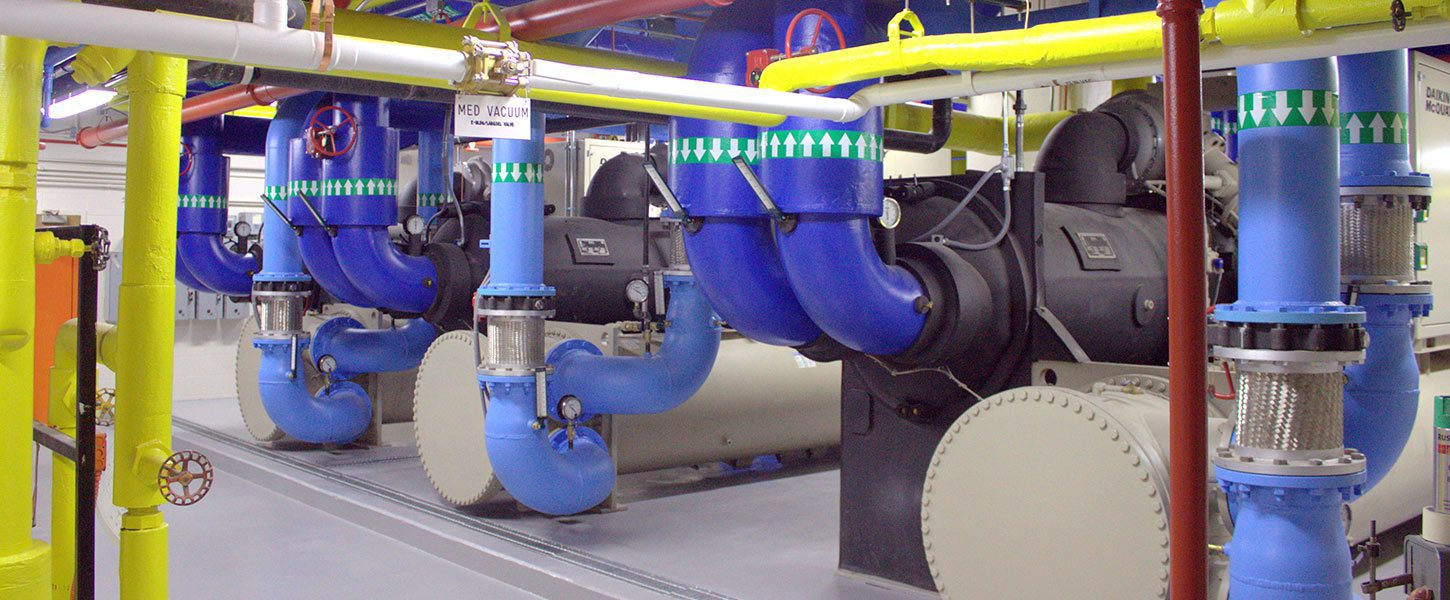

Three new high-efficiency, 700- ton chillers with variable frequency drives (VFDs) and magnetic bearing compressors were installed. The design included the conversion of the cooling system to variable primary flow configuration from a primary/secondary arrangement and the installation of all new premium-efficiency motors. New cooling towers with VFDs resulted in a temperature difference design change from 10°F to 12°F to reduce flow and pumping energy usage.

Four existing air-cooled chillers were replaced with new high-efficiency chillers, including:

- One 250-ton unit (EER 9.9, IPLV EER 19.3), serving the surgery AHU.

- Two 170-ton units (EER 9.4, IPLV EER 17.3) and one 90-ton unit (EER 9.7, IPLV EER 15.4), serving other high-load areas. Addition of these units reduces the need for the main chiller plant to operate year-round.

The new air-cooled chillers are designed with higher efficiency pumping systems. All chillers were selected using life cycle cost analysis to minimize total cost of ownership over the next 30 years. The refrigerant does not have ozone-depletion potential.

The main chiller plant now has N+1 redundancy, improving serviceability and reliability of the plant as a whole. Three main chilled water pumps were installed on a header, allowing any one pump to be out of service at any time. Condenser water pumps are also on a common header.

GBA helped Advocate obtain ComEd rebates as a result of the new energy efficient design, including:

- $28,525 for the 250-ton air-cooled chiller and pump VFDs

- $31,640 for the 170-ton air-cooled chillers

- $5,252 for the 90-ton air-cooled chiller

- $203,700 for the three 700-ton centrifugal chillers, pump VFDs and cooling tower fan VFDs.

The project resulted in estimated energy savings of over $100,000 per year. The total operating efficiency of the new plant is between 0.42 – 0.56 kW/ton, including pumps and cooling towers.

Photo courtesy of Power Construction