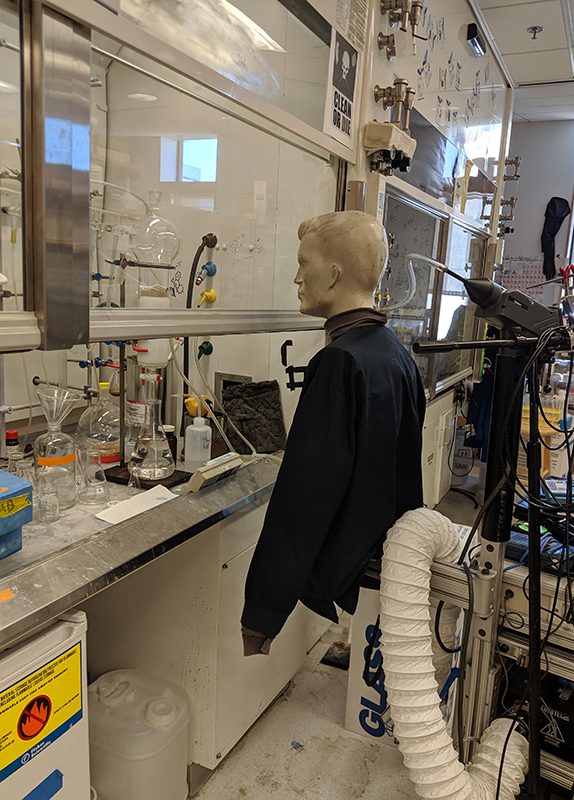

university of chicago, searle chemistry laboratory

Retro-commissioning provided significant savings for this fume-hood-heavy facility.

The Response

GBA developed two sets of measures: seven facility improvement measures (FIMs) to address issues with building systems, and 16 energy conservation measures (ECMs) intended to address the university’s focus on energy conservation, cost management, and environmental stewardship.

No-cost and low-cost measures included the following:

- Fume hood face velocity reduction to 80 fpm vs. the prior 100 fpm.

- Fume hood minimum airflow reduction from 375 internal hood ACH to 200.

- Sash management initiative, including reactivation of automatic closers plus user training. Trend reports were set up in the building automation system to allow the client to pull updated data for individual fume hood performance. This data is then entered into a template spreadsheet to provide standard outputs to be disseminated to the building occupants.

- Removal of redundant AHU pre-filters.

- AHU supply air temperature reset.

- Nighttime space temperature setback.

- Re-implementation of static pressure reset (after fixing valve/ductwork issues).

- Adjustment of cleanroom humidification setpoints to reduce simultaneous humidification and dehumidification.

- Correction of cleanroom simultaneous heating/cooling at fan coil units.

- Lobby terminal unit controls modification to fix simultaneous heating/cooling.

- Revision of mechanical room fan coil unit controls.

- Humidifier control adjustment for AHU-3.

- Replacement of incandescent lamps in the lobby.

In addition, a review of data center use determined that false load has been required to keep the cooling equipment operating consistently. This led to the recommendation that data equipment should be moved from other buildings into this data center so the false load could be replaced with actual equipment load.

Exterior photo © HGA / Anton Grassl

Hood face velocity and flow reduction

Nighttime space temperature setback

Sash management initiative

Static pressure reset

ASHRAE Illinois and Region VI awards

The Results

kWh savings

Mlb steam savings

Ton-hours CHW savings

%