Northwestern University, Ryan Fieldhouse and Walter Athletics Center

Commissioning uncovered key issues that led to improvements in this $270 million sports facility.

The Response

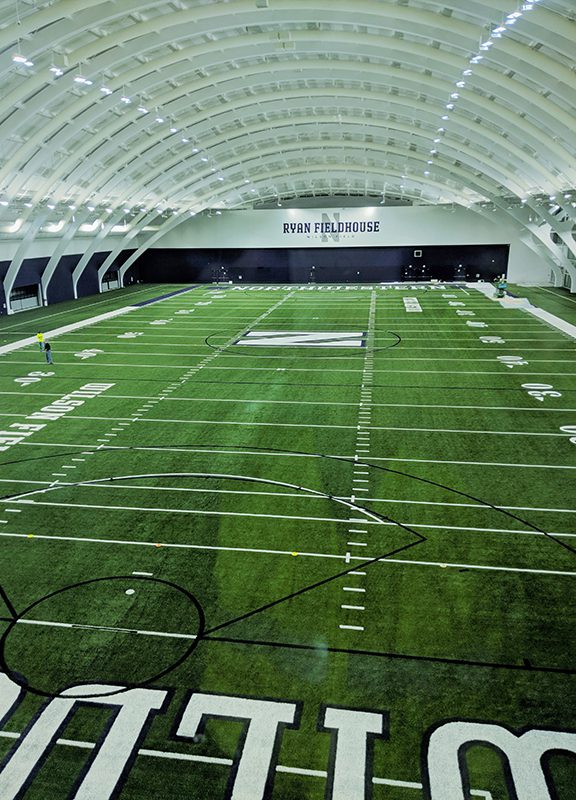

Ryan Fieldhouse and Walter Athletics Center is a large complex with widely varied internal conditions, incorporating study spaces, showers, conference rooms, hydrotherapy pools, and a full-sized indoor football practice field. This wide variety of space conditions provided a back- drop for the project team to work through several issues and system improvements identified during commissioning.

- The Cx team observed inconsistent fire damper installation on the AHUs in the field. Many AHUs were found to have fire dampers isolating some portion of the supply and return airflows, but not the entire airflow, as required by code. This situation had arisen through a combination of miscommunication and inconsistent trade The Cx team quickly alerted the full project team and helped identify the affected units. This allowed the owner to direct changes and to maintain occupant safety.

- The office, meeting, and study spaces are conditioned by chilled beam units, with exterior spaces receiving additional warmth from radiant heating. The provided chilled beam units lacked the inlet requirements that the project team had been expecting but hadn’t specified. The units had a narrower band of acceptable inlet air pressure than intended. This diminished the stability and fine control of the chilled beam system as a whole. The commissioning team worked to test, modify, and retest the chilled beam sequences of operation with the installed condition. Ideas from the owner, commissioning provider, and controls contractor all contributed to improved system stability and increased occupant comfort during a historically cold winter.

- The fieldhouse is supplied primarily with air from overhead fabric ducts, but also receives supplemental conditioning along a wall of windows from terminal units on the floor below. During testing, the Cx team found that these units were each controlled with an individual thermostat at the field level, regardless of what neighboring units were Adjacent units were found to be in full heating and full cooling mode in an effort to provide a balanced space temperature. The Cx team worked to control these units in concert, to prevent energy loss through simultaneous heating and cooling.

LEED Gold certification was targeted and is pending.

The Building Commissioning Association recognized this project with its Building Award (New Construction), 2019.