northern trust

An iconic commercial building in downtown Chicago received a new, energy efficient chiller plant in this GBA-designed upgrade.

The Response

GBA first performed an energy audit, establishing potential savings that would result from a chiller plant retrofit. At the time of the audit, the chiller plant consisted of three chillers installed in 1964, each with a capacity of 884 tons and a cooling efficiency of 0.88 kW/ton. Upgrading to high-efficiency units would yield impressive cost savings and greater reliability; existing equip- ment was well past its estimated service life.

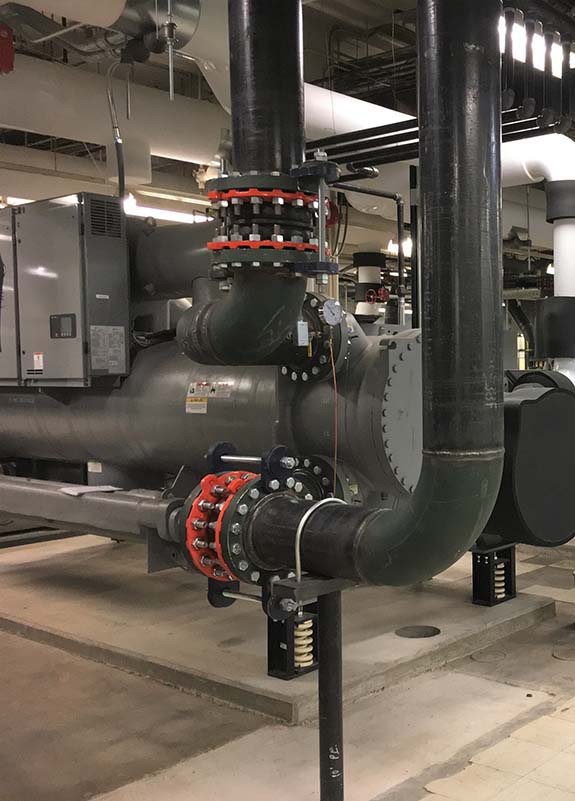

- The new plant includes four Carrier 23xrv variable-speed screw chillers, each with a nominal capacity of 550 tons at AHRI conditions (518 tons with 25% ethylene glycol and project-specific flow rates and temperatures). Full-load efficiency is 0.555 kW/ton, with an IPLV of 0.329 kW/ton. N+1 redundancy is available even on peak days.

- Ozone-depleting refrigerants were eliminated.

- New high-efficiency primary chilled water and condenser water pumps were added on a common header, allowing any combination of chillers and pumps to operate. Pump power (in terms of W/gpm) was reduced by 29% compared with the prior configuration, and additional reductions will be achieved through variable-primary control. Peak kW/ton for the property was reduced by 37%, and IPLV is estimated to be reduced by more than 50%.

- GBA performed a life-cycle cost analysis to select chillers that would provide the best net benefit, considering energy efficiency, operational costs, and first cost of the machines. The client then pre-purchased the chillers for installation by the contractor.

- Overall, the project came in $240,000 under budget and also earned $219,000 worth of incentives from ComEd, the local electric utility.

Exterior Photo: Courtesy of Northern Trust

Four variable-speed screw chillers, for N+1 redundancy even on peak days

Ozone-depleting refrigerants eliminated

New high-efficiency pumps on a common header

Life-cycle cost analysis to guide chiller purchasing

$219,000 in utility company incentives