G/BA’s work at a hospital, commercial property, and university lab was recently honored with the ASHRAE – Region VI Technology Award. The first place projects include: 222 S. Riverside Plaza in the Commercial Buildings – EBCx category; Elmhurst Memorial Hospital in the Health Care Facilities – EBCx category; and University of Chicago – The Knapp Center for Biomedical Discovery in the Educational Buildings – EBCx category.

These projects were previously awarded the 2016 Excellence in Engineering award by the Illinois Chapter of ASHRAE.

222 South Riverside Plaza, Mechanical Value-Add Improvements

222 South Riverside Plaza is a 1.2 million-square-foot, 34-story office building in downtown Chicago. Originally constructed in 1971, the building sits atop the terminal for Chicago Union Station.

The facility was acknowledged for the various MEP upgrades and energy efficiency improvements that occurred during a seven-month period of 2016. Additional improvements are under way.

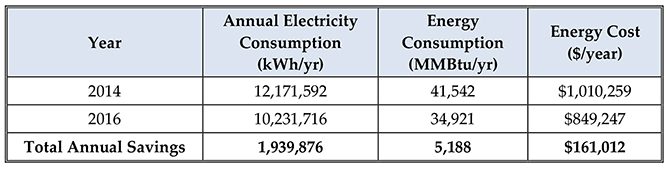

As part of the building’s acquisition by a new owner in 2014, owner’s rep JLL hired G/BA to perform an energy study, create a full-building energy model, design the recommended improvements, and commission the new systems. Since changes began to be implemented, the building’s electricity use is down 16%. Baseload energy consumption has been reduced by 14%, and cooling energy consumption has been reduced by 32%.

The following chart documents current performance.

The upgrades included both capital projects and controls strategy adjustments. Variable air volume terminal units were provided for floor-by-floor quadrant control, converting the entire air distribution to VAV. Four elevator machine room HVAC systems were replaced with new, higher efficiency models. Adding variable frequency drives on two of the chillers, the chilled water pumps, river water pumps, tenant condenser water pumps, cooling tower fans, and supply and exhaust/return fans increased operational efficiency. This upgrade will also prolong the life of the chillers, pumps, and fans. Changes in controls included a complete conversion to a more modern building automation system, as well as various reset strategies, setpoint changes, and sequence modifications.

The project’s energy use reductions have obvious positive environmental effects. Fans operating at lower speeds result in reduced filter replacements and waste. Optimization of the discharge air temperature control reduces chiller run time and therefore cuts refrigerant use. Reduced chiller operation also cuts water use, accompanied by reductions in condensate waste, sewer discharge, and related treatment.

The project was a collaborative effort that involved not only the G/BA team and JLL, but also significant input from the facilities staff and controls contractors. GBA staff John Tsingas, Fiona Martin, Mike Murphy, Andrew Milleville and Alexander Schultz were recognized for their ability to resolve issues, maintain design integrity, and improve energy efficiency.

Elmhurst Memorial Hospital, Monitoring-Based Commissioning

Elmhurst Memorial Hospital (EMH) is an 866,000-square-foot, state-of-the-art acute care facility with 259 private beds, a high-tech emergency services department, and technologically advanced surgical suites. The $450 million hospital, which opened in 2011, has 15 air-handling units delivering 540,000 CFM; a 5,500-ton chiller plant; and a 2,400-bhp steam boiler plant.

EMH gained recognition for results of commissioning mechanical, electrical, plumbing, and related building automation system controls, as well as a new central heating and cooling plant. Grumman/Butkus Associates partnered with Schneider Electric (the software provider and controls contractor) to implement a comprehensive monitoring-based commissioning (MBCx) program at the hospital as part of the ComEd Smart Ideas energy efficiency program. MBCx is a method of achieving energy savings by analyzing data collected from the building automation system (BAS).

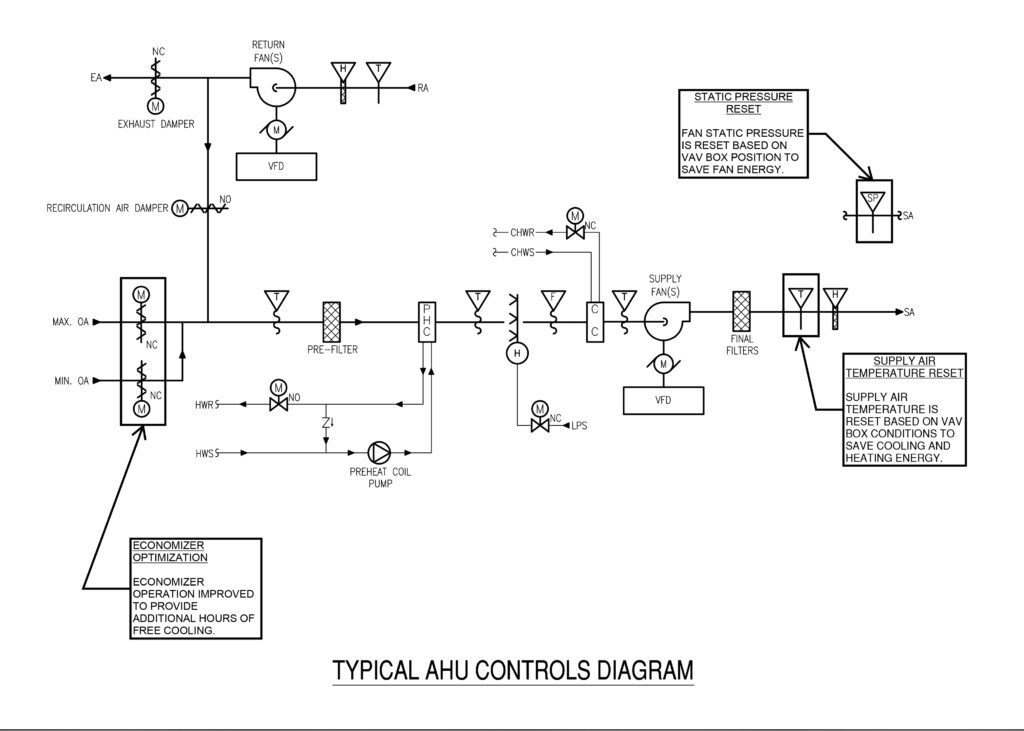

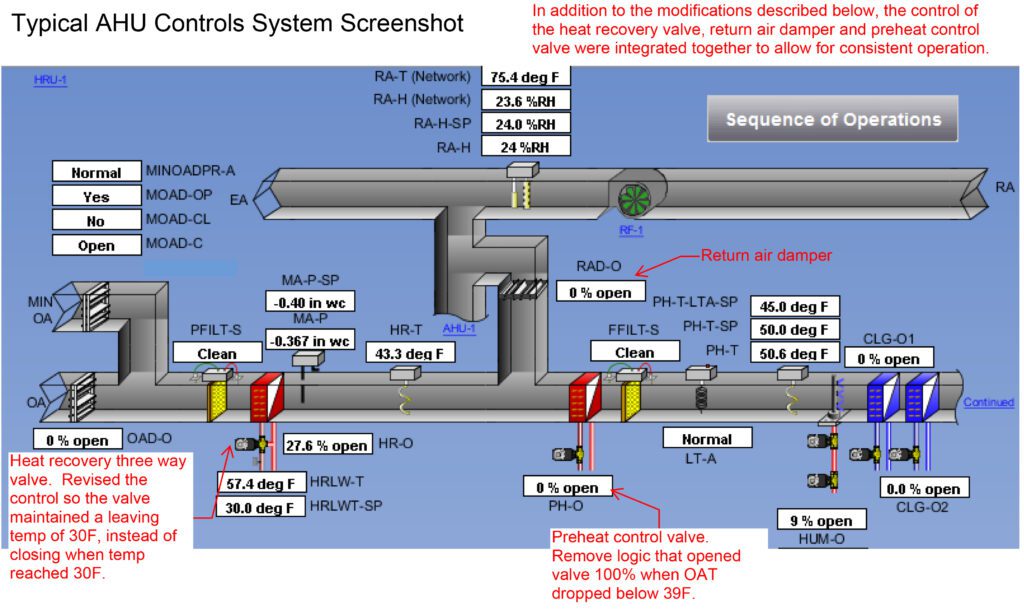

Above: AHU controls diagram, Elmhurst Memorial Hospital

The 18-month analysis consisted of applying various algorithms to the data, seeking energy saving opportunities, maintenance issues, and indoor air quality issues. G/BA and Schneider periodically reviewed the results of the software analysis to look for energy saving opportunities. Energy calculations were also performed to quantify potential energy savings.

A total of seven energy conservation measures were implemented during the project, with a total verified annual savings of 794,000 kWh ($36,000) and 74 kW in demand savings. Measures included supply air temperature reset, condenser water temperature reset, economizer optimization, static pressure reset, and chilled water and hot water differential pressure reset. The simple payback for the project was 1.3 years.

G/BA staff members John Villani, Matt Butkus, and Tim Shinnick were praised for the MCBx effort, which is at the forefront of technology for the commissioning field.

University of Chicago Knapp Center, Retro-Commissioning

The Knapp Center for Biomedical Discovery (KCBD) is a 330,000-square-foot building completed in 2009. The University of Chicago’s Division of Biological Sciences facility provides labs, a vivarium, and office space for research groups including the Institute for Pediatric Molecular Sciences, which is devoted to the genetic influence of childhood diseases.

KCBD was recognized for the results of retro-commissioning services that were completed in two phases between 2014 and 2015. G/BA retro-commissioned the facility as part of the ComEd Smart Ideas incentive program. The first phase aimed to identify and implement low-cost, short-payback energy conservation measures to improve sustainability and reduce operating costs. The second phase focused on larger capital projects.

Though the RCx project targeted energy efficiency, some ongoing operational problems were revealed during early planning. Building staff believed that the heating system capacity was inadequate, but RCx investigation identified multiple issues that were preventing the system from working as designed. The steam system, air handling units, and controls sequences were all involved. G/BA determined that a holistic approach would be necessary, and that correcting these issues individually would not solve the problem.

G/BA identified and corrected the unstable heating and steam systems, which allowed the heating system to use return air properly and the energy recovery system to improve energy efficiency. Annual savings of 88,000 therms were verified.

Phase I was funded by ComEd and resulted in verified savings of $106,000 per year, with a payback of less than a year. Phase II found additional low-cost controls modifications and equipment repairs that could improve the building operation instead of major design modifications.

G/BA staff members John Villani, Kurt Matsen, and Tim Shinnick were recognized for their innovative RCx approach, which included detailed site investigations and data analysis to make the building more efficient with the existing equipment.