Trend Sumo™, G/BA’s new in-house analytics software, is an HVAC trend data review application tool built to identify faults and energy savings opportunities.

By analyzing trend data, engineers can better understand building system performance across a multitude of real-world conditions over the course of weeks or months. Without Trend Sumo, however, finding potentially significant patterns can be time-consuming, requiring examination of hundreds of thousands of data points.

Trend Sumo helps automate trend data analysis, so our team can dig deeper and find more savings for clients. The software leverages trending exports from existing building automation systems (BAS), without requiring clients to implement a new software application.

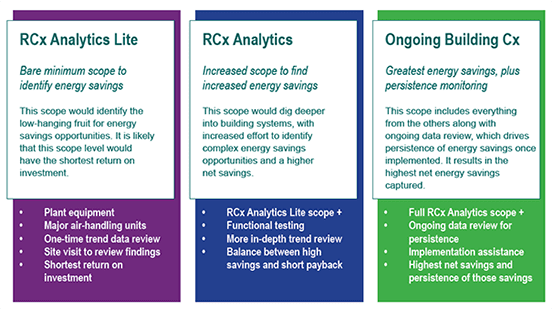

The analysis timeline is flexible, and no long-term contracts are required. The scope of projects involving Trend Sumo is tailored to client needs and can scale to fit project objectives. The tool can be used to perform a one-time analysis of exported trend data or integrated as a monitoring-based commissioning solution on select BAS.

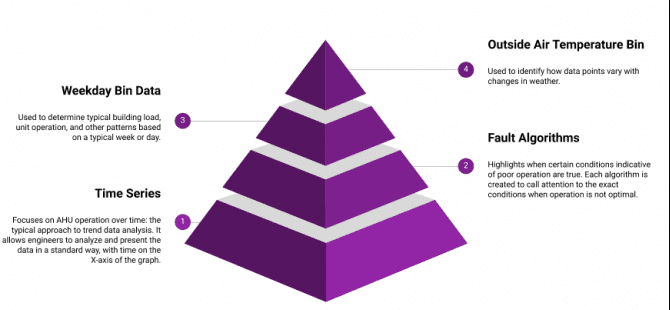

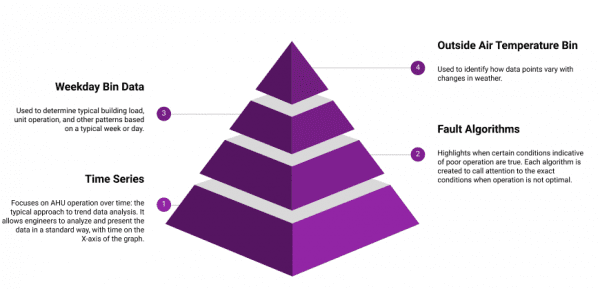

Trend Sumo data perspectives

By using multiple data perspectives, Trend Sumo helps to clarify issues and highlight inefficiencies that might be missed if only a single perspective were considered.

The software automates examinations of four key types of data: weekday bin data, time series, outside air temperature bin data, and fault algorithms (below).

Implementing Trend Sumo

To use the software effectively, the BAS must meet a few simple parameters:

- The BAS can record and store trend data.

- The BAS can export trends or provide access to a trend database.

- Energy savings and proper equipment operation are primary objectives.

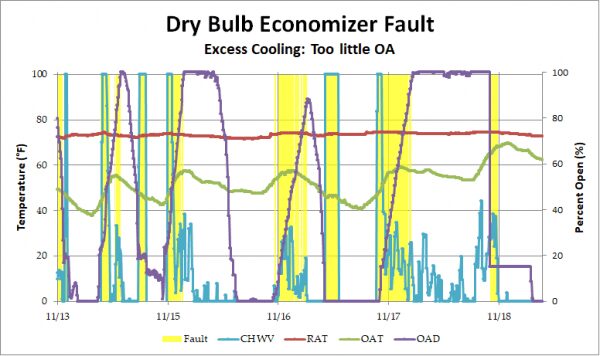

Data output and graphs highlight identified improvement opportunities. For instance, the graph below uses a fault algorithm perspective to highlight periods when an air-handling unit is in a fault condition (yellow). In this case, the unit is using mechanical cooling (chilled water) rather than bringing in more outside air to condition the space. The fault view encourages engineers to dig deeper to determine the root cause(s) for incorrect operation.

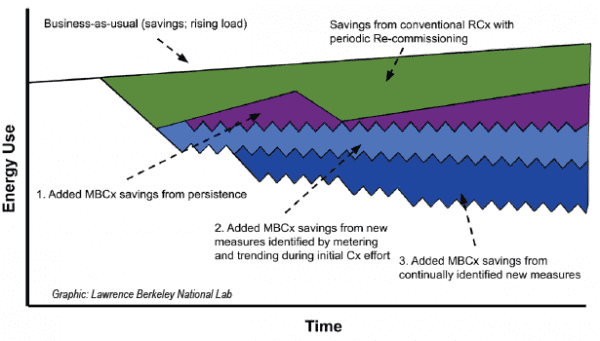

Continuous monitoring, energy and operation improvement persistence

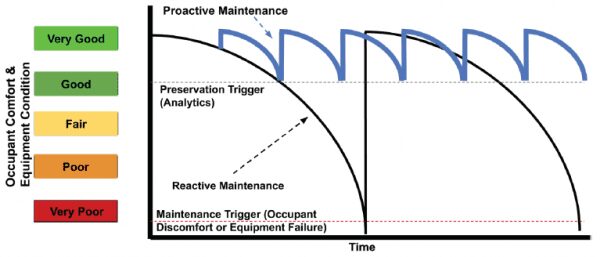

Continuous monitoring saves more energy and leads to a proactive approach to operations and maintenance. This results in improved zone control, increased occupant comfort, and potentially higher satisfaction scores from those who occupy the space.

Rather than relying on hot and cold calls or large-scale degradation of system operation over time to trigger required maintenance, monitoring system data with analytics can help identify issues earlier, giving staff time to respond before a substantial drop in occupant comfort.

To contact a G/BA engineer with questions about using Trend Sumo in your facility, email us (info@grummanbuktus.com).